The experiments carried out in the 90's, gave Fruit Control Equipments the initial impulse for the study and elaboration of a new technology that represented the evolution of the controlled atmosphere and successively UO formulae. By that time, taking advantage of the experience gained, and improving the initial technology. The Blueice India method corresponds to a cycle repeated over time of the initial oxygen stress phase followed by the ULO phase, placing great attention on the CO² concentration variations inside the store based on the variety of the fruits, combined with some quality control tests on the stored product.

The Blueice India project application requires above all optimal gas tightness and should be applied in cells containing the same variety of apple When loading the fruit into the cells, a representative sample of the various lots inside the cell of 8-10 crates must be placed in front of the hatch each containing 3-5 apples from each lot. During the stress period, quality control checks should be taken out for samples. The successive gas stress periods and their conditions are decided on the basis of analytical results with particular reference to the apples ethanol content which may be carried out with an easy to use a kit by the fruit warehouse technician or Fruit Quality Control manager.

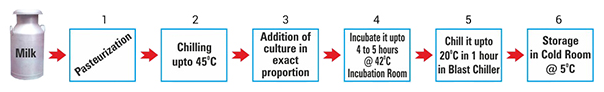

Are you finding the procedure to produce best quality curd In our Indian culture, 'dahi' (Gujrati, Marathi, Nepali, Punjabi, Urdu), 'dohi' (Oriya), Mosou (Kannada) or thayir (Tamil) is the yogurt of India, know for its characteristic, sweet tart test semi sold consistency. It is also Religiously as well as Scientifically proven good for health. But We can’t retain its test and quality equal due to variations in indian weather conditions and slight deviations in procedure so as a solution of that BLUE ICE provides you exact methodology with appropriate temperature conditions on base of our wide experience and some expert's advice

Blue Ice offers indigenous equipments ranging for positive temperature and negative temperature applications. For larger refrigeration equipments, Blue Ice offers imported equipments from sourcing partners.

An incubation chamber is a device used to grow and maintain plants and microbiological cell. They are designed to maintain optimal temperature, humidity, light, pressure, vacuum and other conditions such as the carbon dioxide (CO2) and oxygen content of the atmosphere inside the chamber.

Incubators are typically maintained at around 37 degrees Fahrenheit for optimal growth of cell cultures. Deviations in temperature might inhibit growth and destroy cultures.

An incubator is a device used to grow and maintain microbiological cultures or cell cultures. The incubator maintains optimal temperature, humidity and other conditions such as the CO2 and oxygen content of the atmosphere inside.