What are the Major Components of a Banana Ripening Chamber?

Have you ever seen the bananas your competitors sell and wondered how they are able to sell perfect bananas in almost every season? Or has it been with you that you need to wait for months and months to let your banana rip?

Well, let us tell you that you are not alone! Making sure that your consumers get the right kind of banana with the greatest quality, taste, and shelf life is the crux of any banana business.

To achieve this goal of providing high-quality bananas at the right time, you need to have a banana ripening chamber. These chambers make sure that your banana gets the right environment so that you can sell high-quality bananas year-round, regardless of external weather conditions or storage limitations.

But what exactly are banana ripening chambers and what are the major components of it? Understanding how chambers work can help you choose the right equipment for your business.

In this blog, we are going to explore the primary benefits of banana ripening chambers and how they work together to achieve the perfect ripening environment.

So let's get started without any further delay!

Before we get into the nitty-gritty of banana ripening chamber components, let's understand what a banana ripening chamber is.

What is a Banana Ripening Chamber?

Simply put, a banana ripening chamber controls the temperature, humidity, and airflow of a container to control and accelerate the natural ripening process of bananas.

As more and more people are becoming quality-conscious, the demand for banana ripening chambers is becoming very high day by day among distributors and retailers.

Now that you know what a ripening chamber is, let's have a look at its five major components!

5 Major Components of a Banana Ripening Chamber

As banana ripening depends on many factors, each component revolves around different aspects to help the banana achieve optimal ripening conditions. Here are these components.

-

1. Insulated Chamber Structure

The first and foremost component of the banana ripening chamber is the insulated structure. This structure is responsible for maintaining stable temperature and humidity levels while preventing external factors like weather or ambient temperature fluctuations in the ripening process.

Plus, these chambers are made of high-quality and durable materials like polyurethane panels to nail the temperature levels while being energy efficient.

One thing you need to consider while checking the banana ripening chamber cost is the thickness and quality of the insulation. When you choose a chamber that has effective insulation, you can get better results from your investment.

-

2. Refrigeration System

Another component of a ripening chamber is the refrigeration system as it helps maintain the precise temperatures needed for ripening.

Unlike the normal cold storage solutions that are used for preserving fruits, banana ripening chambers operate at a specific temperature range of 13–15°C.

Choosing a chamber with an effective refrigeration system not only optimizes the ripening process but also reduces operating costs by minimizing energy consumption.

Want to discuss how you can ripe your bananas in the most effective way? Talk to our team today!

-

3. Ethylene Gas Generator

Moving forward, the next component of the banana ripening chamber is Ethylene gas. It is a natural plant hormone that triggers and regulates the ripening process in bananas and many other fruits.

To talk specifically about the banana ripening chamber, an ethylene gas generator releases controlled amounts of ethylene to stimulate the ripening process effectively.

Compared to other alternatives available, this is a safer and faster alternative that allows bananas to ripe naturally even across large batches.

Make sure that your chamber is releasing an appropriate amount of ethylene as too much gas can accelerate ripening too quickly, while too little may cause inconsistencies.

-

4. Humidity Control System

The humidity control system is another important component of a banana ripening chamber. The secret of ripping bananas evenly lies in maintaining the right humidity levels as it directly affects the quality and texture of the banana.

One of the main functions of humidity control is to prevent excessive moisture loss as it causes bananas to shrivel or become discolored. For bananas to rip evenly, the ideal humidity should be around 90-95% as it keeps the fruit moist and vibrant without encouraging mold or bacterial growth.

To make sure the banana ripening process happens correctly, the humidity control system includes components such as humidifiers, dehumidifiers, and sensors that continuously monitor and adjust moisture levels.

-

5. Ventilation and Air Circulation System

Last but not least, ventilation and air circulation systems are also crucial components of the banana ripening chamber.

This system makes sure that all other systems like temperature, humidity, and ethylene gas are working properly and are distributed evenly throughout the chamber.

Ventilation and air circulation systems typically include fans, ducts, and air exchange mechanisms, all designed to maintain the flow of fresh, conditioned air that is required for bananas to ripe properly.

Now that you know what are the major and important components of a ripening chamber, you must be wondering how much a banana ripening chamber costs, right?

Let’s find that out in the next section!

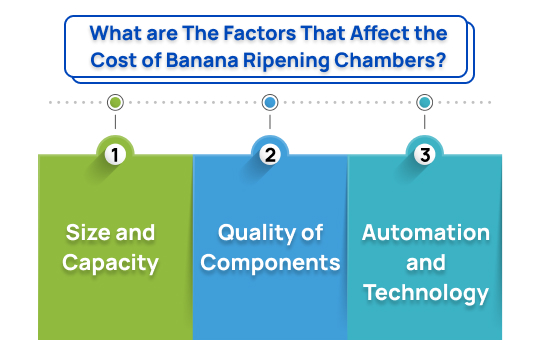

What are The Factors That Affect the Cost of Banana Ripening Chambers?

To evaluate the cost of ripening chambers, you will first need to understand the factors that affect the cost of ripening chambers.

Here is the list of factors that influence the banana ripening chamber cost -

-

Size and Capacity :

Larger chambers with higher capacities naturally cost more due to the increased material and equipment needs.

-

Quality of Components :

High-quality materials, advanced control systems, and efficient refrigeration systems can increase costs but offer durability and better results in the long run.

-

Automation and Technology :

The benefits of Banana Ripening Chambers go beyond waste reduction. With lower waste, businesses get better market prices. Chambers keep bananas at their best quality for consumers and retailers. More demand means higher prices & better profitability. A business can build a premium brand image and keep customers by providing consistently good bananas.

Each of these factors contributes to the chamber’s performance and lifespan, making them important considerations when investing in a ripening chamber.

Get The Best Quality Banana Ripening Chamber from Blue Ice India

If you want to achieve consistent, high-quality bananas, you need to make sure you have a good-quality banana ripening chamber.

Blue Ice India offers a range of high-quality banana ripening chambers, designed with advanced technology and superior materials to meet industry standards.

With a focus on efficient refrigeration, controlled ethylene gas release, and humidity regulation, Blue Ice India provides a comprehensive solution that meets the demands of the fruit industry.

For reliable performance and value, consider Blue Ice India for your banana ripening needs - a quality that ensures your bananas are perfectly ripened and ready for market.

Frequently Asked Questions

A banana ripening chamber is a controlled environment designed to regulate temperature, humidity, and airflow to accelerate the natural ripening process of bananas. It ensures consistent quality, taste, and shelf life, allowing businesses to provide high-quality bananas year-round regardless of external weather conditions.

Key components include an insulated structure for stable temperature and humidity, a refrigeration system to maintain 13–15°C, an ethylene gas generator for controlled ripening, a humidity system to ensure 90-95% humidity, and a ventilation system for even distribution of conditions.

The humidity control system in a banana ripening chamber maintains an ideal humidity level of 90-95%, which prevents bananas from shrivelling, discolouration, and excessive moisture loss. This system includes humidifiers, dehumidifiers, and sensors to ensure uniform ripening and maintain the quality of the fruit.